Top Suppliers Nickel Alloy Inconel 617 UNS N06617 Factory for Czech

Assume full responsibility to meet all demands of our clients; achieve continuous advancements by promoting the growth of our clients; become the final permanent cooperative partner of clients and maximize the interests of clients for Top Suppliers Nickel Alloy Inconel 617 UNS N06617 Factory for Czech, Looking to the future, a long way to go, constantly striving to become the all staff with full enthusiasm, one hundred times the confidence and put our company built a beautiful environment, advanced products, quality first-class modern enterprise and work hard!

HY617 Material grades and equivalents

Inconel 617/ UNS N07617 / SEW VDIUV W.Nr.2.4663 NiCr23Co12Mo / AFNOR NC22KDA

HY 617 is a solid-solution, strengthened, nickel-chromium-cobalt- molybdenum alloy with an exceptional combination of high-temperature strength and oxidation resistance. The alloy also has excellent resistance to a wide range of corrosive environments, and it is readily formed and welded by conventional techniques.

The combination of high strength and oxidation resistance at temperatures over 1800°F (980°C) makes HY617 an attractive material for such components as ducting, combustion cans, and transition liners in both aircraft and land-based gas turbines.

HY 617 Chemical composition:

|

Alloy |

% |

Ni |

Cr |

Fe |

C |

Mn |

Si |

Mo |

Co |

Al |

Ti |

P |

S |

|

617 |

Min |

20 |

0.05 |

8 |

10.0 |

0.6 |

0.2 |

||||||

|

Max |

Rest |

23 |

2.0 |

0.1 |

0.7 |

0.7 |

10.0 |

13.0 |

1.5 |

0.6 |

0.012 |

0.008 |

HY 617 Physical properties:

|

Density |

8.4 g/cm3 |

|

Melting Point |

1330-1380℃ |

Corrosion Resistance

elevated temperatures, those elements cause the formation of a thin, subsurface zone of oxide particles.

The zone forms rapidly upon exposure to high temperatures until it reaches a thickness of 0.001 to 0.002

in. (0.025 to 0.05 mm). The oxide zone provides the proper diffusion conditions for the formation of a

protective chromium oxide layer on the surface of the metal. It also helps to prevent spalling of the

protective layer.

HY 617 has excellent resistance to carburization. Table 9 compares alloy 617 and some other

carburization-resistant alloys in a gaseous carburizing environment at 2000°F (1095°C). The weight-gain

measurements indicate the amount of carbon absorbed during the test period. The composition of INCONEL alloy 617 includes substantial amounts of nickel, chromium, and aluminum for

a high degree of resistance to oxidation and carburization at high temperatures. Those elements, along

with the molybdenum content, also enable the alloy to withstand many wet corrosive environments.

Heat Treatment

HY 617 is normally used in the solutionannealed condition. That condition provides a coarse grain

structure for the best creep-rupture strength. It also provides the best bend ductility at room temperature. Solution

annealing is performed at a temperature of 2150°F (1175°C)for a time commensurate with section size.

Cooling should be by water quenching or rapid air cooling.

| Regular shape for all kinds of alloys | |||

| Form | Specification | Supply Form | Others |

| Sheet | Thickness:0.40-4.75mm,General Width:1000、1219、1500mm | Whole Coil or piece of it | Cold Annealed,Surface 2B、2E |

| Plate | Thickness:4.76-60mm,Width:1500、2000、2500mm,Length:3000、6000、8000、8500mm(Under 10mm plate can be coiled) | Whole Coil or piece of it | Single hot rolling,Solid solution annealed state,Surface 1D |

| Belt | Thickness:0.10-3.0mm,Width:50-500mm | Whole Coil or Specified size | Cold Annealed,Surface 2B、2E |

| Bar & Rod | Rolled barΦ5-45mm,Length≤1500mm | Polished Bar(circle、Square) | Solution annealing,descaling |

| Forged barΦ26-245mm,Length≤4000mm | |||

| Weld tube | Outer diameterΦ4.76-135mm,Wall Thickness0.25-4.00mm,Length:≤35000 mm | Base on your requirement | |

| Seamless Tube | Outer diameterΦ3-114mm,Wall Thickness0.2-4.5mm | Base on your requirement | |

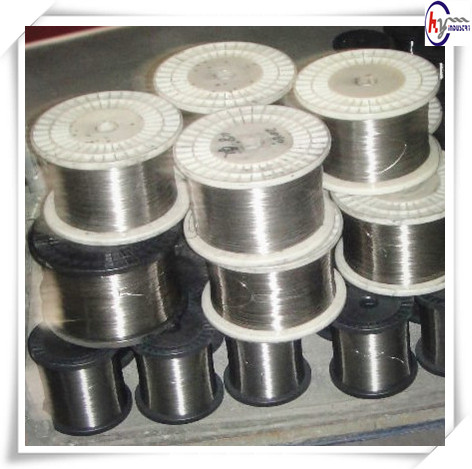

| Wire | Outer diameterΦ0.1-13mm | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

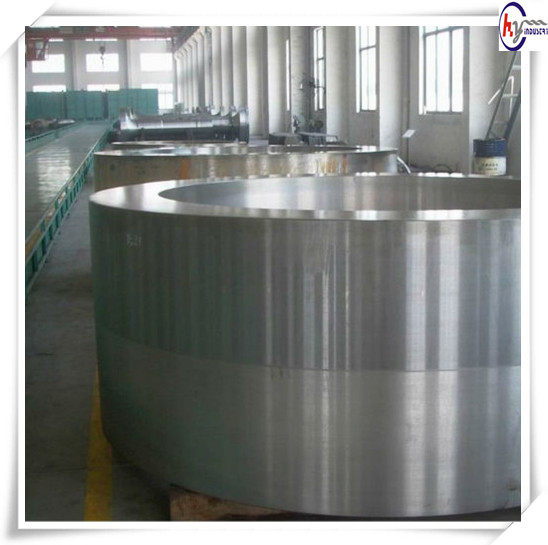

| Forged piece | discs,rings,squares,blocks,slabs | Base on your requirement | Steel, Alloy |

| Flangs | All kinds of Flangs | Base on your requirement | Steel, Alloy |

| Welding Material | Coil wire Φ0.025mm-1.6mm | Base on your requirement | Certificate of Origin:America, Sweden, Britain, Germany, Austria, Italy, France. |

| Straight WireΦ1.6mm-4.0mm | |||

| Welding rodΦ1.2mm-4.0mm | |||

| Tube | Elbow, three links, four links, different diameter size | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

| Explosive bonded laminate | Raw Sheet Thickness≥2mm | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

I am earning my own wedding day band from Inconel X-750 just to be diverse. The material is a agony to do the job with thanks to the superior nickel/chromium articles. The lathe is a LeBlond “dual generate” with an Aloris-copy device article. I built an adapter for the one.25″ boring bar socket to sleeve it down to a 5/8″ side-lock drill shank. I utilised an indicator to sweep the device holder, inserting it instantly on center. The drill is a Seco CrownLoc As well as with .625″ tip, running at around 80sfm, hand feed with plenty of stress, and drenched in reducing oil (not demonstrated in pic). Chips had been astonishingly limited of course, I had to withdrawal the device numerous moments to eliminate chips, due to the fact they weren’t becoming flushed by coolant.

Visit my site for additional Recommendations, Films, Do it yourself assignments and additional:

http://www.mjlorton.com/

—————————–Click “Display additional”—————————————

A information on making use of the correct applications to crimp connectors, strip wire and implement warmth shrink.

You should guidance my information generation by making use of my Amazon Retail store:

http://astore.amazon.com/m0711-twenty

Purchase these applications and connectors below: http://astore.amazon.com/m0711-twenty?node=ten&site=one

——————— Click “Display additional” ——————————-

My site and forum:- http://www.mjlorton.com

Donations and contributions:- http://www.mjlorton.com

My techie channel MJLorton – Solar Power and Digital Measurement Products – http://www.youtube.com/MJLorton

My Techie Amazon Retail store: http://astore.amazon.com/m0711-twenty

My other channel VBlogMag – For nearly any matter beneath the sun! – http://www.youtube.com/VBlogMag

My VBlogMag Amazon Retail store: http://astore.amazon.com/vblogmag-twenty

———————————————————————–

=================================================

Online video sponsor, Pass Ltd – their internet websites:

http://www.tester.co.united kingdom/?cmid=QmhzQjcxYjVlc1E9&afid=bFcwbzliNzVDc289&ats=K2EyUjZNTDh3UTA9 – Examination Products and Examination-meter suppliers and

http://www.calibrate.co.united kingdom/?cmid=QmhzQjcxYjVlc1E9&afid=bFcwbzliNzVDc289&ats=S3Yxd2tOMjVISzA9 – Calibration and support of exam tools

=================================================

Additional dialogue and link to NASA information below:

http://mjlorton.com/forum/index.php?matter=244.

In this online video:

* Deciding upon the correct wire gauge (AWG – American Wire Gauge) for the crimp connector.

* Employing the correct applications to strip the insulation from the wire.

* The correct way to insert the wire into the crimp connector

* Employing the correct crimp applications to crimp the connector

* How to implement warmth shrink accurately to the wire and crimp connector.