Wholesale Dealers of Cobalt Alloy Waspaloy Alloy UNS N07001 for Ethiopia Factory

We insist on the principle of development of 'High quality, Efficiency, Sincerity and Down-to-earth working approach' to provide you with excellent service of processing for Wholesale Dealers of Cobalt Alloy Waspaloy Alloy UNS N07001 for Ethiopia Factory, Contact with us today! We are ready for the market service now!

HY Waspaloy Material grades and equivalents: W.NR 2.4654; UNS N07001; GH4738

Introduction:

HY Waspaloy Alloy is a nickelbase, age hardenable super alloy with excellent high temperature strength and good corrosion resistance, notably to oxidation, at service temperatures up to 1200°F (650°C) for critical rotating applications, and

up to 1600°F (870°C) for other, less demanding, applications. The alloy’s high-temperature strength is derived from its solid solution strengthening elements, molybdenum, cobalt and chromium, and its age hardening elements, aluminum and titanium. Its strength and stability ranges are higher than those typically available for alloy 718.

HY Waspaloy Chemical composition:

| Alloy | % | Ni | Cu | Al | Zr | B | Cr | Mo | Fe | Co | C | Mn | Si | Ti | P | S |

| HY Waspaloy | Min. | Balance | 1.20 | 0.02 | 0.003 | 18.00 | 3.5 | 12.0 | 0.02 | 2.75 | ||||||

| Max. | 0.5 | 1.60 | 0.12 | 0.01 | 21.00 | 5.0 | 2.0 | 15.0 | 0.1 | 1.0 | 0.75 | 3.25 | 0.03 | 0.03 |

HY Waspaloy Physical properties:

| Density | 8.19 g/cm3 |

| Melting point | 1330℃-1360 ℃ |

HY Waspaloy Applications Fileds:

HY Waspaloy is used for gas turbine engine components that call for considerable strengthand corrosion resistance at high operating temperatures. Current and potential applications include compressor and rotor discs, shafts, spacers, seals, rings and casings, fasteners and other miscellaneous engine hardware, airframe assemblies and missile systems.

| Regular shape for all kinds of alloys | |||

| Form | Specification | Supply Form | Others |

| Sheet | Thickness:0.40-4.75mm,General Width:1000、1219、1500mm | Whole Coil or piece of it | Cold Annealed,Surface 2B、2E |

| Plate | Thickness:4.76-60mm,Width:1500、2000、2500mm,Length:3000、6000、8000、8500mm(Under 10mm plate can be coiled) | Whole Coil or piece of it | Single hot rolling,Solid solution annealed state,Surface 1D |

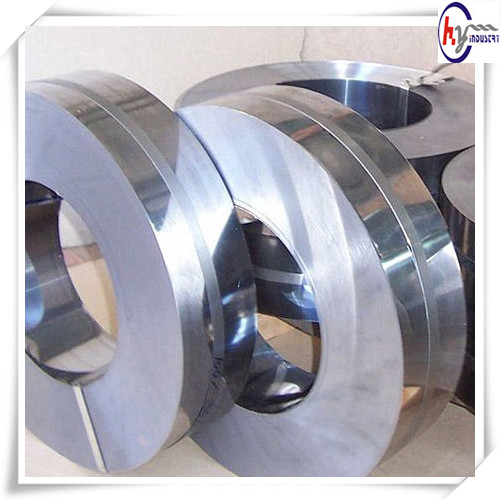

| Belt | Thickness:0.10-3.0mm,Width:50-500mm | Whole Coil or Specified size | Cold Annealed,Surface 2B、2E |

| Bar & Rod | Rolled barΦ5-45mm,Length≤1500mm | Polished Bar(circle、Square) | Solution annealing,descaling |

| Forged barΦ26-245mm,Length≤4000mm | |||

| Weld tube | Outer diameterΦ4.76-135mm,Wall Thickness0.25-4.00mm,Length:≤35000 mm | Base on your requirement | |

| Seamless Tube | Outer diameterΦ3-114mm,Wall Thickness0.2-4.5mm | Base on your requirement | |

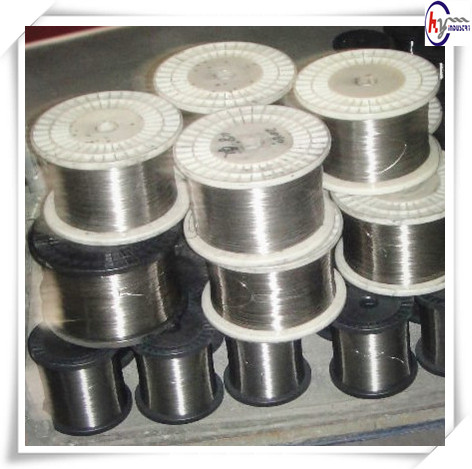

| Wire | Outer diameterΦ0.1-13mm | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

| Forged piece | discs,rings,squares,blocks,slabs | Base on your requirement | Steel, Alloy |

| Flangs | All kinds of Flangs | Base on your requirement | Steel, Alloy |

| Welding Material | Coil wire Φ0.025mm-1.6mm | Base on your requirement | Certificate of Origin:America, Sweden, Britain, Germany, Austria, Italy, France. |

| Straight WireΦ1.6mm-4.0mm | |||

| Welding rodΦ1.2mm-4.0mm | |||

| Tube | Elbow, three links, four links, different diameter size | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

| Explosive bonded laminate | Raw Sheet Thickness≥2mm | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

» Metal Tubes India is a GOVT. OF INDIA Acknowledged STAR EXPORT Dwelling & PED Accredited Maker

» Metal Tubes India is winner of All India Award for export excellence for 6 Consecutive Many years

» Metal Tubes India is an ISO 9001,ISO 14001,OHSAS 18001 Accredited company, our international CRISIL Ranking is SE 2B

» Metal Tubes India is European Force Machines Directive PED-97/23/EC qualified company

Ni 72., Cr fifteen.5, Fe 8. Mn 1. C .fifteen Cu .5 Si .5 S .015

Significant Efficiency Alloys stocks and produces this grade in the adhering to forms: Bar, wire, sheet, plate, coil, fasteners and forgings. Ask for quote on this grade.

Alloy 600 is a nickel-chromium alloy built for use from cryogenic to elevated temperatures in the selection of 2000 deg F(1093 deg C). The superior nickel material of the alloy allows it to retain substantial resistance less than lessening conditions and makes it resistant to corrosion by a range of natural and inorganic compounds. The nickel material gives it exceptional resistance to chloride-ion pressure-corrosion cracking and also offers exceptional resistance to alkaline options.

Inconel 600 Tube

ASME SB-163 ASME SB-516 ASME SB751 AMS 5580

UNS N06600 also offered in numerous forms like cap, elbow, erw pipes, fasteners, fittings, flange, plate, reducer, spherical bar, seamless pipes, sheet, tee and tube at industrial charge.

+ for extra info & specification about Inconel 600 remember to check out

http://www.steeltubesindia.internet/

Substantial Temp Nickel Centered & Tremendous Alloys – Mechanical Homes Inconel Round Bar, Plate Sheet Offer – Inconel is designed of Mostly Nickel and a number of other aspects. The origin coming from Supernovas. Inconel is a Tremendous Alloy and Michlin Metals sells Inconel Round Bar, Hex Bar, Flat Bar, Plate, Sheet, Tube and Pipe.