Wholesale price for Cobalt Alloy Waspaloy Alloy UNS N07001 for Rio de Janeiro Factories

Our company since its inception, always regards product quality as enterprise life, continuously improve production technology, improve product quality and continuously strengthen enterprise total quality management, in strict accordance with the national standard ISO 9001:2000 for Wholesale price for Cobalt Alloy Waspaloy Alloy UNS N07001 for Rio de Janeiro Factories, We will wholeheartedly welcome all clients in the industry both at home and abroad to cooperate hand in hand, and create a bright future together.

HY Waspaloy Material grades and equivalents: W.NR 2.4654; UNS N07001; GH4738

Introduction:

HY Waspaloy Alloy is a nickelbase, age hardenable super alloy with excellent high temperature strength and good corrosion resistance, notably to oxidation, at service temperatures up to 1200°F (650°C) for critical rotating applications, and

up to 1600°F (870°C) for other, less demanding, applications. The alloy’s high-temperature strength is derived from its solid solution strengthening elements, molybdenum, cobalt and chromium, and its age hardening elements, aluminum and titanium. Its strength and stability ranges are higher than those typically available for alloy 718.

HY Waspaloy Chemical composition:

| Alloy | % | Ni | Cu | Al | Zr | B | Cr | Mo | Fe | Co | C | Mn | Si | Ti | P | S |

| HY Waspaloy | Min. | Balance | 1.20 | 0.02 | 0.003 | 18.00 | 3.5 | 12.0 | 0.02 | 2.75 | ||||||

| Max. | 0.5 | 1.60 | 0.12 | 0.01 | 21.00 | 5.0 | 2.0 | 15.0 | 0.1 | 1.0 | 0.75 | 3.25 | 0.03 | 0.03 |

HY Waspaloy Physical properties:

| Density | 8.19 g/cm3 |

| Melting point | 1330℃-1360 ℃ |

HY Waspaloy Applications Fileds:

HY Waspaloy is used for gas turbine engine components that call for considerable strengthand corrosion resistance at high operating temperatures. Current and potential applications include compressor and rotor discs, shafts, spacers, seals, rings and casings, fasteners and other miscellaneous engine hardware, airframe assemblies and missile systems.

| Regular shape for all kinds of alloys | |||

| Form | Specification | Supply Form | Others |

| Sheet | Thickness:0.40-4.75mm,General Width:1000、1219、1500mm | Whole Coil or piece of it | Cold Annealed,Surface 2B、2E |

| Plate | Thickness:4.76-60mm,Width:1500、2000、2500mm,Length:3000、6000、8000、8500mm(Under 10mm plate can be coiled) | Whole Coil or piece of it | Single hot rolling,Solid solution annealed state,Surface 1D |

| Belt | Thickness:0.10-3.0mm,Width:50-500mm | Whole Coil or Specified size | Cold Annealed,Surface 2B、2E |

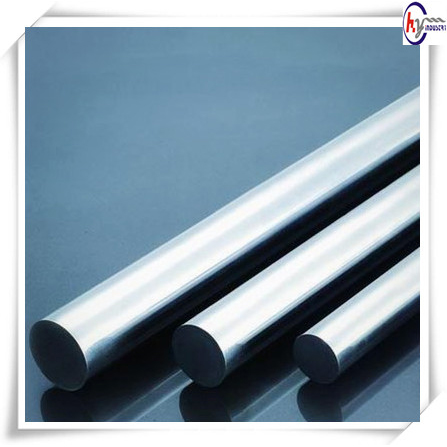

| Bar & Rod | Rolled barΦ5-45mm,Length≤1500mm | Polished Bar(circle、Square) | Solution annealing,descaling |

| Forged barΦ26-245mm,Length≤4000mm | |||

| Weld tube | Outer diameterΦ4.76-135mm,Wall Thickness0.25-4.00mm,Length:≤35000 mm | Base on your requirement | |

| Seamless Tube | Outer diameterΦ3-114mm,Wall Thickness0.2-4.5mm | Base on your requirement | |

| Wire | Outer diameterΦ0.1-13mm | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

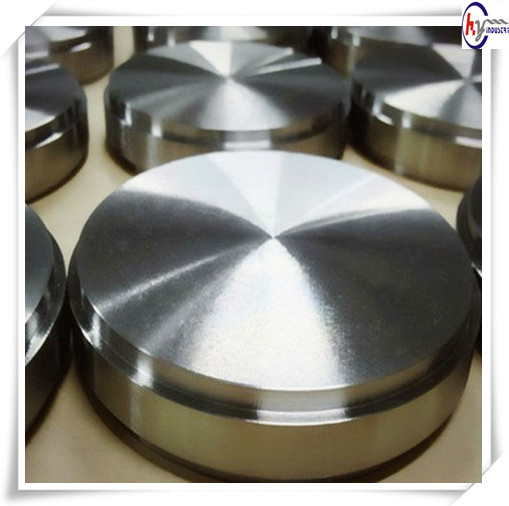

| Forged piece | discs,rings,squares,blocks,slabs | Base on your requirement | Steel, Alloy |

| Flangs | All kinds of Flangs | Base on your requirement | Steel, Alloy |

| Welding Material | Coil wire Φ0.025mm-1.6mm | Base on your requirement | Certificate of Origin:America, Sweden, Britain, Germany, Austria, Italy, France. |

| Straight WireΦ1.6mm-4.0mm | |||

| Welding rodΦ1.2mm-4.0mm | |||

| Tube | Elbow, three links, four links, different diameter size | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

| Explosive bonded laminate | Raw Sheet Thickness≥2mm | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

Discovery and Science Channel’s How It truly is Designed Alloy Wheels episode.

All copyrights go to their respective homeowners.

I am earning my own wedding day band from Inconel X-750 just to be diverse. The material is a agony to do the job with thanks to the superior nickel/chromium articles. The lathe is a LeBlond “dual generate” with an Aloris-copy device article. I built an adapter for the one.25″ boring bar socket to sleeve it down to a 5/8″ side-lock drill shank. I utilised an indicator to sweep the device holder, inserting it instantly on center. The drill is a Seco CrownLoc As well as with .625″ tip, running at around 80sfm, hand feed with plenty of stress, and drenched in reducing oil (not demonstrated in pic). Chips had been astonishingly limited of course, I had to withdrawal the device numerous moments to eliminate chips, due to the fact they weren’t becoming flushed by coolant.