Nickel Alloy Nimonic 80A UNS N07080

HY 80A Material grades and equivalents

Nimonic 80A /UNS N07080 / SEW VDIUV W. Nr. 2.4952 / AFNOR NC20TA

HY N80A Chemaical composition:

|

Alloy |

% |

Ni |

Cr |

Fe |

Mn |

Si |

P |

S |

Al |

Ti |

C |

Co |

B |

Zr |

Cu |

|

80A |

Min. |

Balance |

18 |

1.0 |

1.8 |

||||||||||

|

Max. |

21 |

3.0 |

1.0 |

1.0 |

0.02 |

0.015 |

1.8 |

2.7 |

0.1 |

2.0 |

0.008 |

0.15 |

0.2 |

HY N80A Physical properties:

|

Density |

8.19 g/cm3 |

|

Melting point |

1320-1365℃ |

HY N80 A minimum mechanical properties in the room temperature :

|

Status |

Tensile strength |

Yield strength |

Elongation |

|

HY N80A |

930 |

620 |

20 |

Characteristic as below:

A nickel-chromium alloy similar to NIMONIC alloy 75 but made precipitation hardenable by additions of aluminum and titanium. The alloy has good corrosion and oxidation resistance and high tensile and creep-rupture properties at temperatures to 1500°F (815°C).

Used for gas-turbine components (blades, rings, and discs), bolts, tube supports in nuclear steam generators, die-casting inserts and cores, and exhaust valves in internal-combustion engines.

Specification:

|

Rod, Bar, Wire and Forging Stock |

BS 3076 HR1, ASTM B 637, AECMA PrEn2188, AECMA PrEn2189, AECMA PrEn 2190, AECMA PrEn 2396, AECMA PrEn2397, AIR 9165-37 |

|

Plate, Sheet and Strip |

BS HR 201, AECMA PrEn2191 |

|

Pipe and Tube |

BS HR 401 |

| Regular shape for all kinds of alloys | |||

| Form | Specification | Supply Form | Others |

| Sheet | Thickness:0.40-4.75mm,General Width:1000、1219、1500mm | Whole Coil or piece of it | Cold Annealed,Surface 2B、2E |

| Plate | Thickness:4.76-60mm,Width:1500、2000、2500mm,Length:3000、6000、8000、8500mm(Under 10mm plate can be coiled) | Whole Coil or piece of it | Single hot rolling,Solid solution annealed state,Surface 1D |

| Belt | Thickness:0.10-3.0mm,Width:50-500mm | Whole Coil or Specified size | Cold Annealed,Surface 2B、2E |

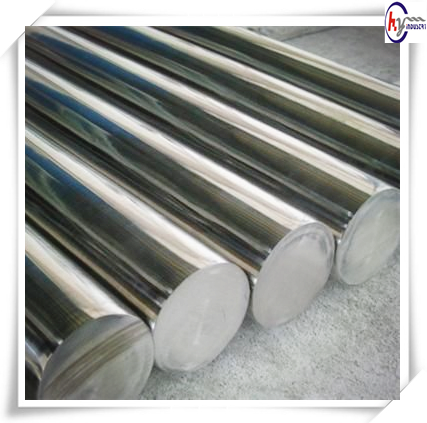

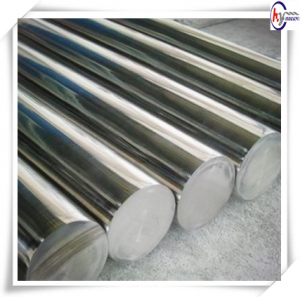

| Bar & Rod | Rolled barΦ5-45mm,Length≤1500mm | Polished Bar(circle、Square) | Solution annealing,descaling |

| Forged barΦ26-245mm,Length≤4000mm | |||

| Weld tube | Outer diameterΦ4.76-135mm,Wall Thickness0.25-4.00mm,Length:≤35000 mm | Base on your requirement | |

| Seamless Tube | Outer diameterΦ3-114mm,Wall Thickness0.2-4.5mm | Base on your requirement | |

| Wire | Outer diameterΦ0.1-13mm | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

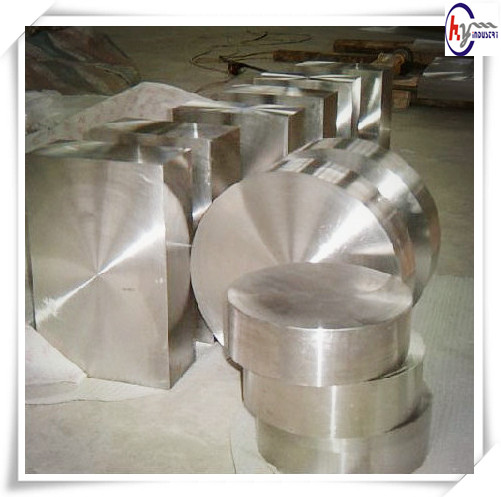

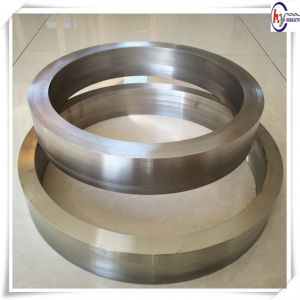

| Forged piece | discs,rings,squares,blocks,slabs | Base on your requirement | Steel, Alloy |

| Flangs | All kinds of Flangs | Base on your requirement | Steel, Alloy |

| Welding Material | Coil wire Φ0.025mm-1.6mm | Base on your requirement | Certificate of Origin:America, Sweden, Britain, Germany, Austria, Italy, France. |

| Straight WireΦ1.6mm-4.0mm | |||

| Welding rodΦ1.2mm-4.0mm | |||

| Tube | Elbow, three links, four links, different diameter size | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |

| Explosive bonded laminate | Raw Sheet Thickness≥2mm | Base on your requirement | Ni & Ni alloy, Ti & Ti alloy |