Nimonic PE16/BS HR55 /BS HR207/AFNOR NW 11AC

Nimonic PE16 Material grades and equivalents

|

Trademark |

BS |

AFNOR |

UNS |

W.Nr |

|

Nimonic PE16 |

BS HR55 BS HR207 |

AFNOR NW 11AC |

Chemical composition:

|

Ni + Co |

Cr |

Mo |

Fe |

Al |

Ti |

C |

|

42-45 |

15.5-17.5 |

2.8-3.8 |

Rem |

1.1-1.3 |

1.1-1.3 |

0.04-0.08 |

|

Cu |

Si |

Mn |

Co |

B |

Zr |

S |

|

0.5 max |

0.5 max |

0.2 max |

2.0 max |

0.005 max |

0.02-0.04 |

0.015 max |

|

Regular shape for all kinds of alloys |

|||

|

Form |

Specification |

Supply Form |

Others |

|

Sheet |

Thickness:0.40-4.75mm,General Width:1000、1219、1500mm |

Whole Coil or piece of it |

Cold Annealed,Surface 2B、2E |

|

Plate |

Thickness:4.76-60mm,Width:1500、2000、2500mm,Length:3000、6000、8000、8500mm(Under 10mm plate can be coiled) |

Whole Coil or piece of it |

Single hot rolling,Solid solution annealed state,Surface 1D |

|

Belt |

Thickness:0.10-3.0mm,Width:50-500mm |

Whole Coil or Specified size |

Cold Annealed,Surface 2B、2E |

|

Bar & Rod |

Rolled barΦ5-45mm,Length≤1500mm |

Polished Bar(circle、Square) |

Solution annealing,descaling |

|

Forged barΦ26-245mm,Length≤4000mm |

|||

|

Weld tube |

Outer diameterΦ4.76-135mm,Wall Thickness0.25-4.00mm,Length:≤35000 mm |

Base on your requirement |

|

|

Seamless Tube |

Outer diameterΦ3-114mm,Wall Thickness0.2-4.5mm |

Base on your requirement |

|

|

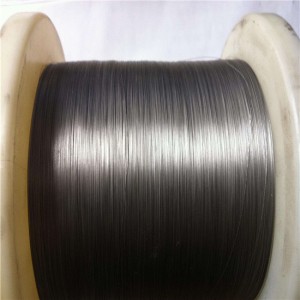

Wire |

Outer diameterΦ0.1-13mm |

Base on your requirement |

Ni & Ni alloy, Ti & Ti alloy |

|

Forged piece |

discs,rings,squares,blocks,slabs |

Base on your requirement |

Steel, Alloy |

|

Flangs |

All kinds of Flangs |

Base on your requirement |

Steel, Alloy |

|

Welding Material |

Coil wire Φ0.025mm-1.6mm |

Base on your requirement |

Certificate of Origin:America, Sweden, Britain, Germany, Austria, Italy, France. |

|

Straight WireΦ1.6mm-4.0mm |

|||

|

Welding rodΦ1.2mm-4.0mm |

|||

|

Tube |

Elbow, three links, four links, different diameter size |

Base on your requirement |

Ni & Ni alloy, Ti & Ti alloy |

|

Explosive bonded laminate |

Raw Sheet Thickness≥2mm |

Base on your requirement |

Ni & Ni alloy, Ti & Ti alloy |

Characteristic as below:

A precipitation-hardenable nickel-iron-chromium alloy with an addition of molybdenum for solid-solution strengthening. It has good strength and oxidation resistance at temperatures to about 1380°F (750°C). The alloy is designed to provide a precipitation-hardened material having excellent hot-working, cold-working, and welding characteristics.

Processing conditions and application:

Used for gas-turbine components and in nuclear reactors.