YG6 UNS C2

YG6 Material grades and equivalents

|

Trademark |

UNS |

ISO |

AISI/ASTM |

|

YG6 |

C2 |

K20 |

|

Chemical composition(mass fraction)(%)

|

Alloy |

WC |

TiC |

TaC (NbC) |

Co |

Other |

|

YG6 |

94 |

- |

- |

6 |

- |

Physical properties &minimum mechanical properties

|

Density/ g/cm |

Min Hardness/HRA |

Tensile strength/MPa |

Impact toughness j/cm |

Min Bending strength/ N/cm2 |

|

| 14.6-15.0 | 89.5 | 1450 | 2.6 | 1380 |

YG6 Characteristic as below:

9High wear resistance, but lower than YG3, YG3X, the toughness is higher than YG3, YG3X, can use higher cutting speed than YG8.

YG6 Processing conditions and application:

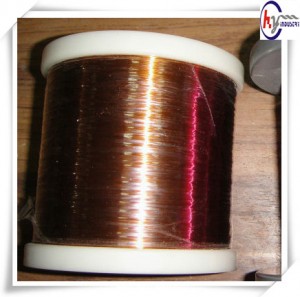

It is suitable for semi finishing of cast iron, nonferrous metal and alloy nonmetal material at medium cutting speed. Used for rough cutting of cast iron, non iron metal and its alloy and non-metallic material in frontier cutting, semi fine car and fine car in discontinuous cutting. It can also be used for drawing die of wire rod, geological exploration, electric drill and wind head for coal mining.